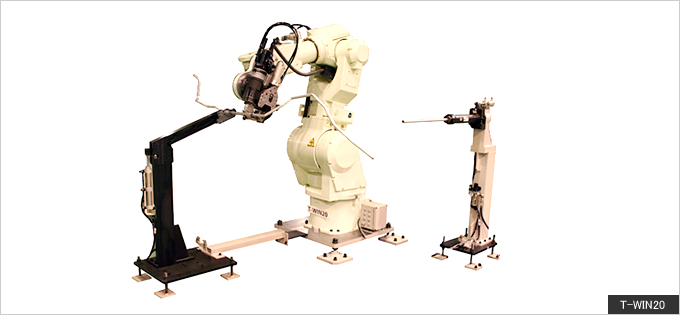

Opton robotic benders in production line for a straight pipe bending with pre-mounted parts and/or rubber hoses

The ultimate robotic bender cell-system for productivity doubled to tripled yet with enhanced quality and labor-saving.

The ultimate robotic pipe bender

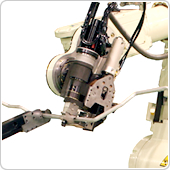

Opton WIN-series Benders – developed as the world only robotic pipe benders – employ the operation manners as easy as other normal and traditional Opton benders. The series has the bending head being mounted atop of the robot arm head that operates in linear- and circular-interpolation for precision-quality DBB, POB and DOB motions.

Opton WIN-series Benders – developed as the world only robotic pipe benders – employ the operation manners as easy as other normal and traditional Opton benders. The series has the bending head being mounted atop of the robot arm head that operates in linear- and circular-interpolation for precision-quality DBB, POB and DOB motions.

Various pipe-chucking designs are offered for free choice out of horizontal chucking of a work piece at its end,intermediate section and vertical chucking as well all for fixing the device on the production floor.

The unprecedentedly unique performances with the Opton Robot Benders includes easy clearance of the robot bending head from colliding during the processes, the resulted bending capability for complicated working specifications with pre-mounted fittings, the bending work simultaneously even at loading/unloading process, bi-directional bending access from either end by using a center chuck and other versatilities depending on user’s application ideas.

A highly effective robotic production line can be designed by setting a stocker for multi-sized work pieces in the post-cutting process of materials.

Opton has supplied many such successful installations in the market with enhanced stability of quality and reduction of production cost that are quite unprecedented in other production systems.

1.Production speed doubled

- Thanks to the robot bending head executing DBB/POB/DOB on a fixed-positioned work piece, resulted swinging-free bending has lead to the production for enhanced accuracy and faster speed.

- Labor-saving production has come in reality with loading/unloading by the robot itself.

- Machining time is saved for two bending processes by the robot performing these two process simultaneously at loading/unloading

- The bending head can accommodate 4 sizes of bending tools thus leading to remarkable reduction of set-up time.

2.Total line productivity enhanced in triple by bending capability of a straight work piece with pre-mounted parts and hoses.

A typical example is that a straight-sized material is handled first for cutting-to-sizes, blur-removal, end-forming, part-brazing and hose-calking, and is then forwarded to the stocker with transfer arm for the robot to pick it up. The robot goes on for loading with simultaneous bending execution for the first bending point and place the work piece on the chuck to continue bending to be completed. All these will bring the total productivity as high as in about three times.

A typical example is that a straight-sized material is handled first for cutting-to-sizes, blur-removal, end-forming, part-brazing and hose-calking, and is then forwarded to the stocker with transfer arm for the robot to pick it up. The robot goes on for loading with simultaneous bending execution for the first bending point and place the work piece on the chuck to continue bending to be completed. All these will bring the total productivity as high as in about three times.

A further advantage is claimed that the bending fixtures have become more simple-designed and/or even eliminated comparing to those with conventional type of bending.

3.Opton Robot Benders available in Series

| Movable bending head type | Fixed bending head type |

|---|---|

| 【T-WIN】 | 【G-WIN】 |

| 5・8・10・15・20・25 | 35・45・50・60・70・80・85・90・100・130・150 |

※Bending capability corresponds between each class of model size between the robot benders and the machines of Opton standard series.

4.Operation method

Working principal and operation manners of the robot benders are same and as easy as those for Opton standard benders.

The knowledge, technique and experiences built-up in the previous production with Opton machines work fully helpful in starting new operation of the robot benders.

5.Machine errors

The robot supplied is of mass-production type and has enough allowance for loading capacity, and very few errors are only expected with the sturdy robots. When the robot falls however into ill condition, the maintenance is support by the network power of the robot manufacturer.