Opton’s CNC pipe benders reputed world-wide for decades long have been totally reviewed

to the new line-ups with varieties of models all for class-top energy-saving performances

1.New generation bender series capacity types 5 to 150 for SMA- or ECO-series

| SMA | ECO |

|---|---|

| 5,8,10,15,20 | 25,35,45,50,50a,60,70,80,85a,90,100,130,150 |

2.For SMA series, all 5 capacity types are available in two types of [E-rank} and [O rank] .

- [E rank] High-end version with all electric powered.

- [O rank] Low-cost version with electric powered and pneumatic equipments.

※Instance : SMA5 E-rank : High-end bender for approximate work size φ5.0.

3.For ECO-series, 13 kinds in capacity has all [E-rank] [C-rank] and [O-rank] for wider choices.

- [E-rank} High-end version with all electric-powered.

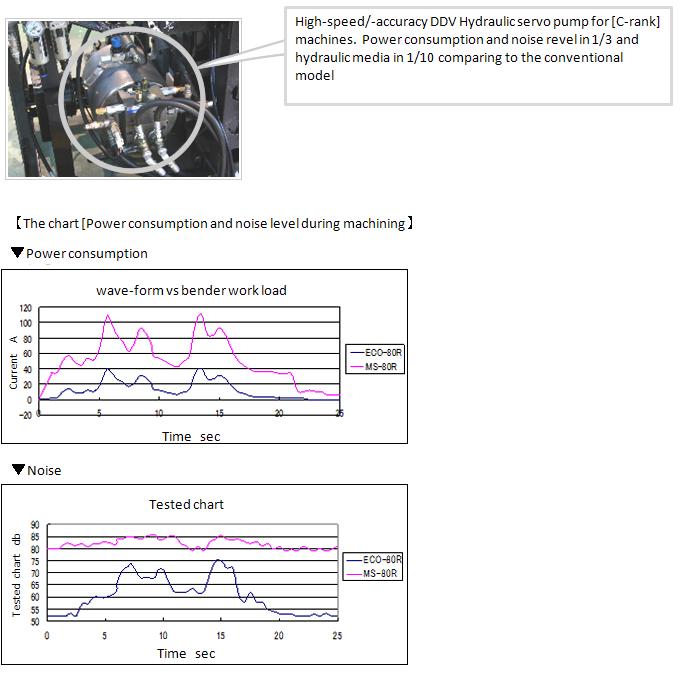

- [C-rank] 1/3 Energy savor version with electric- and DDV hydraulic- powered.

- [O-rank] Low-cost version with electric- and standard hydraulic-powered.

※Instance : ECO-35 C-rank : 1/3 save-energy version for approximate work size φ5.0

40% installation space saving with totally new design

Comparing to old MSO-series machines, the machine has achieved down-sizing in its width and length yet maintaining the same effective length, leading to installation space saved by 40%. Effective length may be optionally extended by every 500mm.

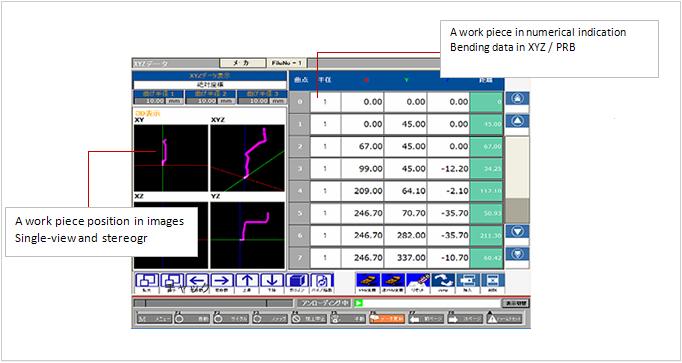

TIF Numerical controller facilitated

Ultimately new-generation type numerical controller (TIF) has been invented for cost-oriented but highly synchronized processing that works the Window OS and the real time OS in collaboration for direct software control of all AC servo drives

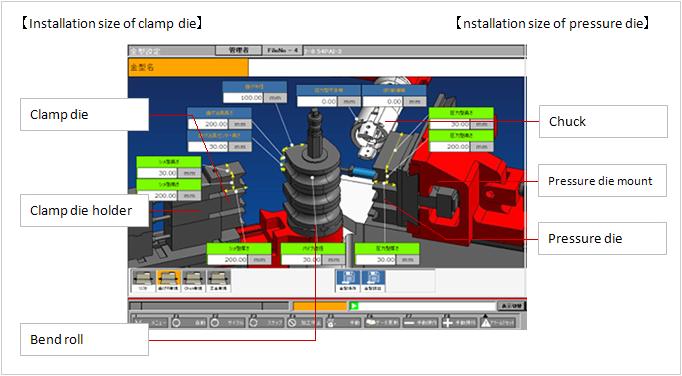

- Enhanced set-up work thanks to a wok design and bending tool installation being guided in the 3D color display

- Enhanced visibility and operability thanks to the latest panel computer with easy touch panel and icons.

- By interfacing to non-contact 3D profiler [Cloudformer] or [MEMS Former] , the tested bending data are compensated and fed back to the bender for right design.

- By interfacing to the production management software [Bend Master], the management for production, machine operation and all bending data can all be collectively controlled.