As an expression of Opton’s appreciation to years long patronage of the products.

Opton is pleased to offer the renewal of these machines by embedding the latest technologies for an extended life in the currently-on-service products.

【Discontinuity of spare parts/components】

The machines at services more than 10 years are likely to face short supply of maintenance parts and components due to their discontinued production at supplier’s side, and the cases are no exception in those for N/C, servo motors etc.。

- Counter-measurement

1、Free machine-check offered

1、Free machine-check offered- For the machine in service more than 10 years may be visually checked by Opton sales engineer in a half-day work for looseness of sliding parts, dusts gathered in the controller box and applicability of the discontinuity listing. This work will be followed by his diagnosing report to the machine user including the type of maintenance required, the related work proposal and the quotation.

- 2、Machine check on charge base

- When 「free machine-check」 is found not enough in finding the machine condition, the check-on-charge-basis may be requested. This includes visual-/tester- inspection for approx. 100 items by an Opton maintenance specialist. This work will be followed by his diagnosing report to the machine user including the type of maintenance required, the related work proposal and the quotation.

- Plan A Plan A for replacement of power source

- ●Maintenance-free AC servo motor is installed in place of DC servo motor that needs motor brush to be replaced if in case.

- ●Low-heating, high-accuracy air-cooled DDV Hydraulic Servo Pump is also installed in place of high-heat generating, low- accuracy, and water-cooled servo valves.

- ●The replacing work is held with a machine at user floor.

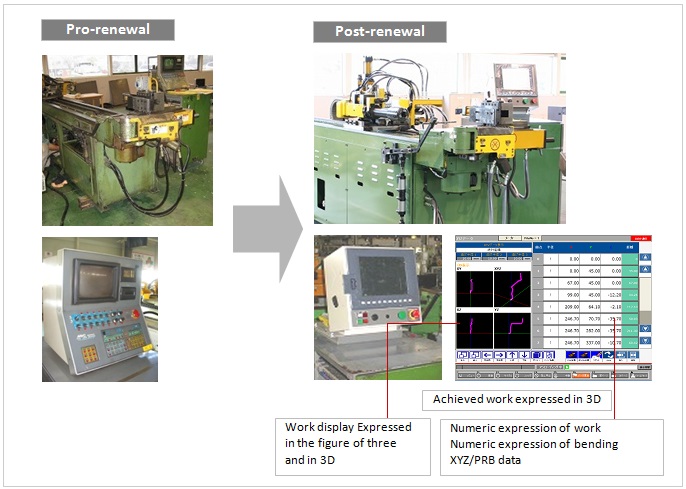

- Plan B Plan B for replacing a whole N/C hardware

- ●32-bit high-processing and –resolution display embedded NC is installed in place of 8-bit, low-performing and hard-to-repair N/C.

- ●The software is also replaced by that of the latest version.

- ●Production speed is expected to increase by 5 to 10%.

- ●A machine for this replacement work needs be brought in and the replacing work is to be held at Opton factory.

- Plan C (Plan C is plan A + plan B to be held together)

- ●In addition to installation of new power-supplying source and a new N/C with software, cleaning/repainting of a machine, part or whole of distribution devices and rubber hoses are also to be replaced.

- ●Cracks being found on machine body during the work of plan C will be followed by repair welding work upon notice to the machine user to recover robust performance with the machine.

- The captioned request is accepted subject to the following conditions

- Opton needs to obtain the bending data-creation format of N/C software, and the machine owner is requested to negotiate for this requirement with N/C supplier on behalf of Opton.

- All checking works are to be held at on-charge basis.