Case of Innovative solutions

Robotic benders ex-Opton, ideal for long-sized work pieces w...

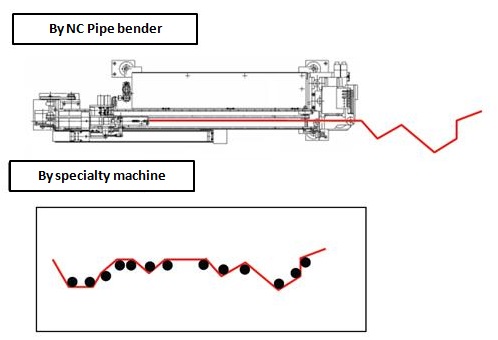

【By conventional way of bending】

・A work piece of small diameter (mainly φ5~φ6) and long size (of longer than

1500 ~2000mm)is normally machined by cross-type N/C pipe bender or specialty

machine.(Note:cross bender = axial motion is made orthogonal to the tooling post.)

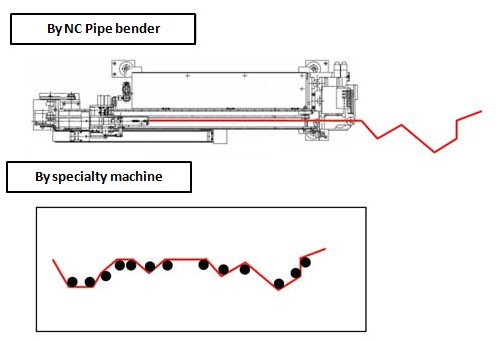

【Production problem prevailing at moment】

・In bending a long-sized work piece, the piece tends to swing out larger especially

when the rear half of the material is at speedy rotation, easily causing poor bent

shape at the end. Alternatively the bending speed must be turned slower at the sector

where larger swinging is seen likely, leading to longer machining time at the end.

・An operator-assist holding of the work piece may be one solution against this problem,

but again the machining time goes longer with higher possibility yet existing for

instable quality production.

・Manufacturing by specialty machine is followed by different problem as the machine

modification will take rather longer time to meet design change of the product.

・Also the specialty machine has no versatility to meet different machining designs

or work pieces specifications.

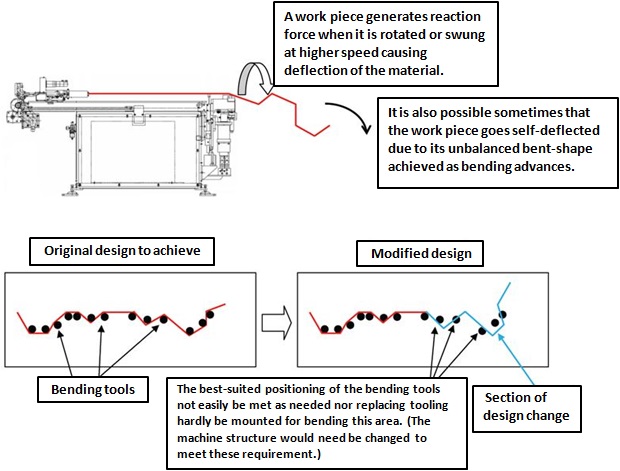

【Bending by the robotic bender】

①Advantages are claimed against standard bending machines for 60%-faster bending

motion and no requirement of unloading device.

②Thanks to remarkable decrease of poor quality bending caused by twisting and

deflection of work piece during bending process, stable bending operation can be

made by at speed- and accuracy-oriented operation with resulted advantage for

higher per-day output.

③A work piece with pre-mounted fittings such as protective tube, rubber hose and/or

stay can also be accepted as the bending robot executes bending motion of DBB and

POB with itself keeping off these fittings

④Versatility of the machine can meet varieties of work specifications and higher

rationalization of production has been achieved.

⑤Three-sized R bending More work specification can be met without time-consuming

tooling changes.

⑥Simulation Software(Optional) can be a powerful engine for prototype work in

time- and material-saving.

※Upon being advised by an inquirer on production factors like material type,

sizes and daily and monthly production requirement, our feasibility study will

be prepared with the best-suited machine.

Enquiry contact

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.