Case of Innovative solutions

Tooling set-up time reduced by 83% ( a case of client S)

<The problem faced by Client>

The case is a work piece sized φ25.4 andφ31.8. Each size needed separate tooling set-up.

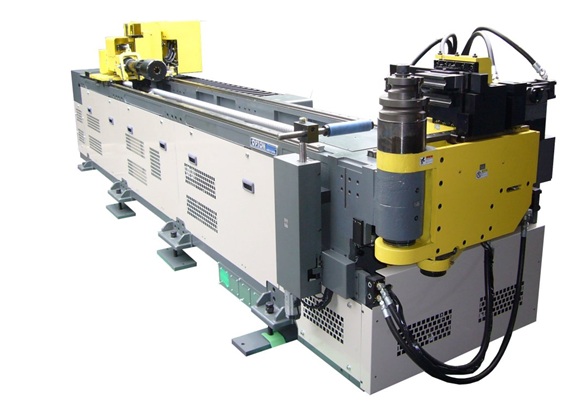

New production bender is invested with strong expectation for time reduction for tooling set-up,

and what has been achieved are just remarkable

Achievement expected

Idea proposed by Opton

1.Multi-stacking of toolings

Roll, clamp die and pressure die

φ31.8⇒R1

φ25.4⇒R2

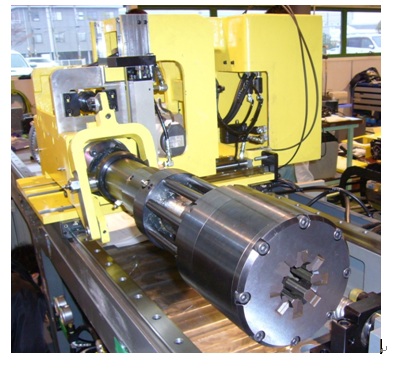

2.Employment of special chuck

Mounting of a multi-capacity chuck to meet the work size of φ22.2~31.8.

結果

The result achieved

By preparing tooling sets in two size plus one multi-chuck e for work size ofφ22.2~31.8,two work sizes can be machined without time-consuming re-setting of tooling.

Remarkable time reduction of tooling set-up has lead to running cost saving.

New ECO Bender can accommodate 5 stacks max. of tooling

By mounting the multi-chuck, many work sizes can be machined without frequent setting of tooling.

Consult with our sales engineer about varieties in three sizes S,M & L available of the multi-chuck

If Opton's 3D Profiler 「Cloud Former 」 is interfaced in line of production,

one-piece testing with the first piece from the production can be immediately fed back to the second piece to continue the run within the specification needed.

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.