L-ECO Pipe Loader/Stocker Sereis

For working with pipes of any kinds and specs all at fully automated processing.

Product outline

● It is very imperative to meet varied market requirement for wider products range and severe production factors of labor cost-saving, easier set-up, higher quality and total cost reduction, etc.

●Loader/ unloader system is very serious for FA manufacturing system when production needs saving, easier set-up, etc..Opton can meet elaborated consultation for and supplying of loader/unloader system with either of standard or most delicate custom specifications.

●Automatic or easier set-up manufacturing may be met for variety production by NC machines that surely bring the manufacturers remarkable advantages in machining time, labor saving and multi-spec production.

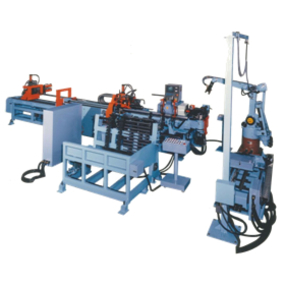

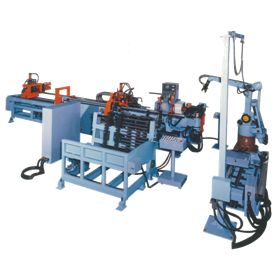

Pipe loader and stocker in a typical case supplied in the market

Here is a representative case of pipe loader with stocker being supplied in the market for L-ECO Bender series.

| Applicable models | L-ECO80,90,100,130,150 "ST/UD/AB/UB/SW" All models |

|---|

1.Pipe Loader

Followings are the representative loading approach.

- Front loading

- Side loading

- Opposite-side loading

- Off-set position loading

- Rear loading

- Robotized loading

1-1.Front loading

A work piece is carried in direct forwarding to and loaded from bender front.

【Features】

- Best used for bending with mandrel, but no mandrel retraction installed.

- Unlimited work piece length can be applied.

1-2.Side loading

A work piece is loaded from the loading device positioned to the side of the machine main frame and towards the "center" side of the bending head.

【Features】- Loading of a work piece made between the front roll and rear chuck for shortest work piece pitching only needed to start bending, and the machine length can be minimized to necessity.

- Total machining floor space can be minimized.

- Mandrel retraction may be needed depending on the work piece length.

1-3.Opposite-side loading

A work piece is loaded from the loading device positioned to the opposite side of the one as described in the article.

【Features】Because the loading device is installed in such position as the bending arm turns away from the loading device, less bending interference is expected.

1-4.Off-set position loading

The loading arm unit on the opposite side loader slides forwards to the offset-position, then the arms swing to load a work piece in the position.

【Features】- Mandrel-assisted bending is allowed but mandrel retraction helpless.

- Ample working space can be squeezed in the bending head area.

1-5.Rear loading

A work piece is loaded from rear of the machine.

【Features】- Advantageous for longer work piece. No mandrel can be used.

- Shorter loss-time is expected for loading.

1-6.Robotized loading

A work piece is loaded by a material handling robot

【Features】- One robot performs both loading and unloading.

- Automation-oriented robotized performance can be implemented for the succeeding process.

- Loading and unloading extended to versatile application .

2.Pipe Stocker

Following are the typical stocker available.

- Flat-arrayed Stocker

- Conveyor Stocker

- Hoist stocker

- Part-feeder Stocker

- Vertical stocker

2-1.Flat-arrayed Stocker

Works pieces are stocked in flat parallel on the guided roller.

- Simple structure and easy to extend to multi-layer stocker.

- Multi-sized 6-stuck NC stocker is the largest specification ever supplied to the market .

2-2.Conveyor Stocker

Work pieces are lined on the conveyor.

- Constant-speeded supply of work pieces without hurting the skin.

- Conveyor types are available in horizontal, slant or vertical feeding.

2-3.Hoist stocker

Work pieces in lot are arrayed in the stocker and an individual piece is hoist to be loaded to the macine.

- Large quantity of work pieces can be stocked. Suitable for machining exhaust pipes and products of large diameter.

- Work piece surface may rather be easier to suffer rubbed scars.

2-4.Part-feeder Stocker

Work pieces are supplied from parts feeder.

- The smallest-sized work pieces can be individually supplied.

- Speed-oriented supply and loading

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

Automated pipe bending with NC benders and robotized benders are important imperative factors for productivity enhancement.

Our years-long, wide and heavy involvements in the industries are sure to meet the client’s concerns in automated manufacturing.