Hydro-forming Machine Series

Hydro-forming machine, only-one-in-the-world with hammering molding, 1/3 power-consumption and 2/3 floor space needed vs conventional machines.

Product outline

●Cost-consuming press molding and/or welder process can be eliminated by one simple hydro-molding.

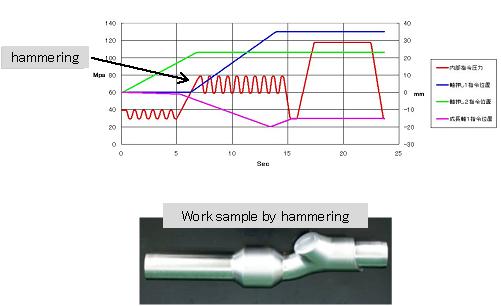

●Opton’s patented 「hammering」impact molding , or pulsative pressure has realized easy thickness transition in molded area, thus successfully raises accuracy and expansion rate of a work piece.

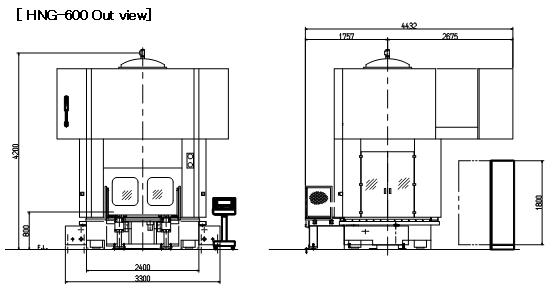

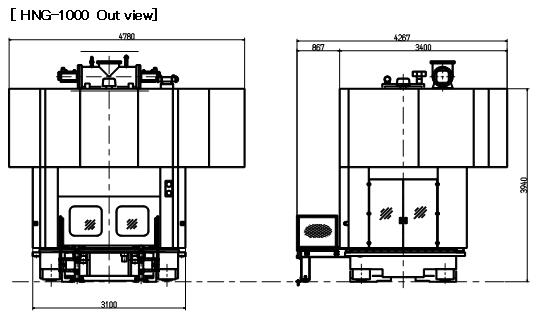

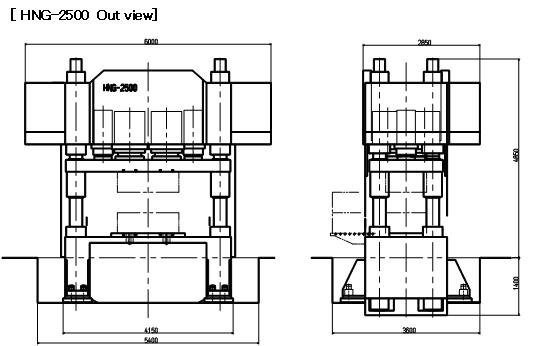

Hydro-forming machines with hammering- molding ( HNG series )

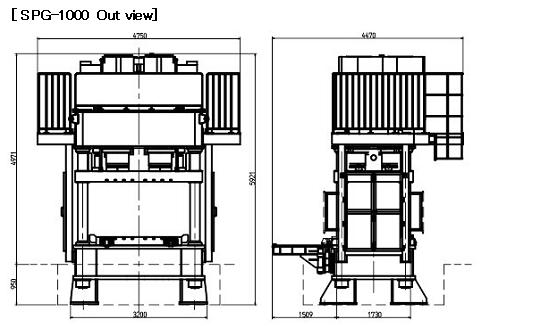

Static-pressured hydro-forming machines (SPG series)

1.Features

- Both series are lined with standard varieties of die clamping force of 1000KN up to 30000KN and with any optional size and capacity to meet client needs.

- Press and/or soldering process is eliminated by molding in one simple hydro-forming process for cost-saving. One master work piece can be machined all for propagation, press and hole-making, which results in process- and cost-cut yet with quality enhancement.

- The "patented" hammering(pulse)-molding (in HNG series) has brought easy material thickness transition, accuracy enhancement and higher expansion rate ,and has broken through the propagation limit often observed in the conventional pressure molding by simply-increased fluid pressure. Hammering molding, or pulsative pressure molding has realized easy thickness transition of material thus for précised and higher expansion rate.

- Wax-less molding has eliminated waxing and its removal. Due to the sliding friction reduced by hammering (pulsative inner-pipe fluid) pressure, the wax-free molding can be applied to a longer work piece which has often needed additional process of waxing.

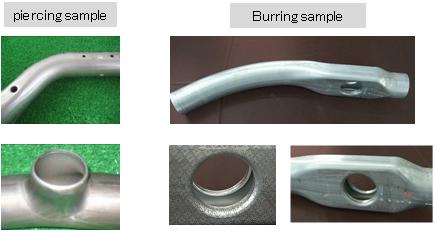

- Piercing and burring also available in this series as optional features.

- DDV hydraulic servo pump are installed for power source for reduction of power consumption, space, heat- and noise- generation. (in HNG series)

- Collaboration of multi-axes, synchronized P-MAC NC and DDV servo pump has brought machining performance in high-end speed and accuracy (HNG series)

- Power consumption at 1/3 of that of conventional machines (HNG series)

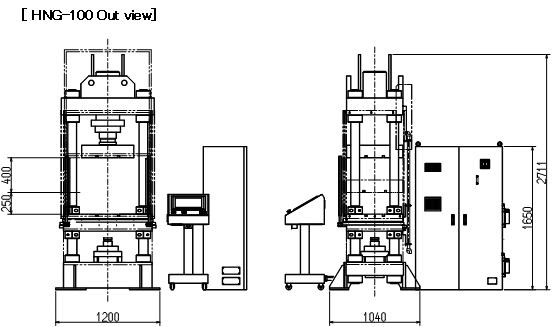

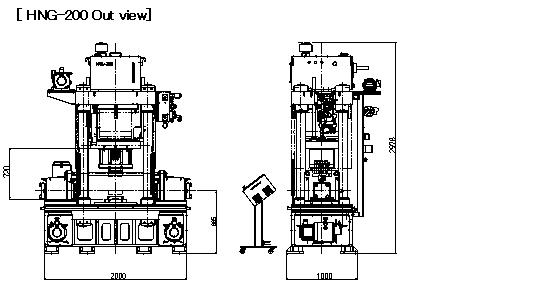

- Installation space needed 2/3 of that of conventional machines (HNG series)

- Automated loading / unloading system as otpion

- Operator friendly ambient noise at 60dB~70dB (HNG series)

Hydro-forming machine with hammering molding

| HNG Series Specification / Model | 100 | 200 | 600 | 1000 | 2000 | 3000 | |

|---|---|---|---|---|---|---|---|

| Main specification | Die Clamping force(kN) | 1,010 | 2,000 | 6,000 | 10,000 | 20,000 | 30,000 |

| Lifting capacity(kN) | 80 | 80 | 190 | 300 | 600 | 900 | |

| Stroke(mm) | 250 | 250 | 300 | 300 | 700 | 700 | |

| Daylight(mm) | 550 | 720 | 900 | 900 | 1,500 | 1,600 | |

| Descension speed(mm/sec) | 200 | 250 | 250 | 250 | 250 | 250 | |

| Die clamp speed(mm/sec) | 15 | 8 | 10 | 6 | 8 | 6 | |

| Ascension speed(mm/sec) | 195 | 200 | 250 | 206 | 250 | 250 | |

| Bolster size(mm×mm) | 600×500 | 700×600 | 1,200×1,000 | 1,500×1,200 | 2,500×1,700 | 3,000×2,000 | |

| Bolster height(mm) | 800 | 800 | |||||

| Weight | 7TON | 8.5TON | 45TON | 55TON | 130TON | 180TON | |

| Die clamp pump | 8/3.5~DDV Hyd-Servo Pump(cc/Kw)~50/25 | ||||||

| Motion axes | Rod cylider | 8/3.5 ~St. installed in upper die DDV hyd-servo pump (cc/Kw)~50/25 | |||||

| Pierce cylinder※3 | 8/3.5~DDV Hyd-Servo Pump(cc/Kw)~50/25 | ||||||

| Hydro supply | Max Flow pressure(MPa) | 200 | 200 | 200 | 200 | 200 | 200 |

| Hydro Flow capacity(L/min) | 2.5 | 2.5 | 10 | 10 | 10 | 10 | |

| Max flow rate(L) | 0.5 | 0.5 | 2.0 | 2.0 | 4.0 | 4.0 | |

| Pressure generator pump | 15/7.5 ~DDV servo pump in common use for die-clamp pump(cc/Kw)~50/25 | ||||||

| Hydro saturation sensor | Automatic | ||||||

| Controller | All axes in motion monitor, dialogue type, High speed, Rigid type, P-MAC multi-axial synchronized NC | ||||||

| Installation floor | Flat floor | Pitted floor | |||||

| Loading device | Manual / Vacuum-hand robot, others | ||||||

| Unloading device | Manual / Conveyor robot, others | ||||||

- *1.Custom-ordered Hydro-forming machine may be accepted for non-standard performances.

- *2.The cylinders are optional for the axes of molding and piercing.

- *3.Hydro-former machines up to the model HNG-1000 are of pit-less type.

Static-pressure Hydro-forming machines

SPG series in table

| SPG series Specification / Model | 100 | 200 | 600 | 1000 | 2000 | 3000 | |

|---|---|---|---|---|---|---|---|

| Main specification | Die Clamping force(kN) | 1,000 | 2,000 | 6,000 | 10,000 | 20,000 | 30,000 |

| Lifting capacity(kN) | - | - | - | - | - | - | |

| Stroke(mm) | 500 | 500 | 900 | 1000 | 1000 | 1,200 | |

| Daylight(mm) | 800 | 1,120 | 1,500 | 1,500 | 2,000 | 2,000 | |

| Descension speed(mm/sec) | 70 | 120 | 200 | 100 | 100 | 100 | |

| Die clamp speed(mm/sec) | 15.0 | 10 | 10 | 10 | 10 | 10 | |

| Ascension speed(mm/sec) | 100 | 70 | 100 | 100 | 100 | 100 | |

| Bolster size(mm×mm) | 630×630 | 900×900 | 1,600×1,600 | 2,000×1,800 | 2,500×2,500 | 3000×2,500 | |

| Bolster height(mm) | - | - | - | - | - | - | |

| Weight | - | - | - | - | - | - | |

| Power source | Die clamp pump | General purpose servo pump | |||||

| Rod cylinder | |||||||

| Pierce cylinder | |||||||

| Hydro supply | Max Flow pressure(MPa) | 200 | 200 | 200 | 200 | 200 | 200 |

| Hydro Flow capacity(L/min) | 2.5 | 2.5 | 10 | 10 | 10 | 10 | |

| Max flow rate(L) | 0.5 | 0.5 | 2.0 | 2.0 | 4.0 | 4.0 | |

| Pressure generator pump | General purpose servo pump | ||||||

| Hydro saturation sensor | Automatic | ||||||

| Controller | PLC | ||||||

| Installation floor | Pitted floor | ||||||

| Loading device | Manual / Vacuum-hand robot, others | ||||||

| Unloading device | Manual / Conveyor robot, others | ||||||

* The standard specification is subject to change without notice.

*1.Custom-ordered Hydro-forming machine may be accepted for non-standard performances.

*2.The cylinders are optional for the axes of molding and piercing.

*3.Hydro-former machines up to the model HNG-1000 are of pit-less type.

Hydro-former mold

The molds (upper- and lower-) , pusher axis, propagation axis are all custom made in reflection to the client product design.

Options

Optional orders may be accepted for automation components including moving bolster, die-lifter, loader, unloader, additional die-components including piercing axis, burring-axis, and propagation axis.

Special designed accessories are also accepted for devices of hydro-oil separator, lighting, safety guard and compliance to foreign regulation.

Series

| HNG Series Specification / Model | 100 | 200 | 600 | 1000 | 2000 | 3000 | |

|---|---|---|---|---|---|---|---|

| Main specification | Die Clamping force(kN) | 1,010 | 2,000 | 6,000 | 10,000 | 20,000 | 30,000 |

| Lifting capacity(kN) | 80 | 80 | 190 | 300 | 600 | 900 | |

| Stroke(mm) | 250 | 250 | 300 | 300 | 700 | 700 | |

| Daylight(mm) | 550 | 720 | 900 | 900 | 1,500 | 1,600 | |

| Descension speed(mm/sec) | 200 | 250 | 250 | 250 | 250 | 250 | |

| Die clamp speed(mm/sec) | 15 | 8 | 10 | 6 | 8 | 6 | |

| Ascension speed(mm/sec) | 195 | 200 | 250 | 206 | 250 | 250 | |

| Bolster size(mm×mm) | 600×500 | 700×600 | 1,200×1,000 | 1,500×1,200 | 2,500×1,700 | 3,000×2,000 | |

| Bolster height(mm) | 800 | 800 | |||||

| Weight | 7TON | 8.5TON | 45TON | 55TON | 130TON | 180TON | |

| Die clamp pump | 8/3.5~DDV Hyd-Servo Pump(cc/Kw)~50/25 | ||||||

| Motion axes | Rod cylider | 8/3.5 ~St. installed in upper die DDV hyd-servo pump(cc/Kw)~50/25 | |||||

| Pierce cylinder※3 | 8/3.5~DDV Hyd-Servo Pump(cc/Kw)~50/25 | ||||||

| Hydro supply | Max Flow pressure(MPa) | 200 | 200 | 200 | 200 | 200 | 200 |

| Hydro Flow capacity(L/min) | 2.5 | 2.5 | 10 | 10 | 10 | 10 | |

| Max flow rate(L) | 0.5 | 0.5 | 2.0 | 2.0 | 4.0 | 4.0 | |

| Pressure generator pump | 15/7.5 ~DDV servo pump in common use for die-clamp pump(cc/Kw)~50/25 | ||||||

| Hydro saturation sensor | Automatic | ||||||

| Controller | All axes in motion monitor, dialogue type, High speed, Rigid type, P-MAC multi-axial synchronized NC | ||||||

| Installation floor | Flat floor | Pitted floor | |||||

| Loading device | Manual / Vacuum-hand robot, others | ||||||

| Unloading device | Manual / Conveyor robot, others | ||||||

| SPG Series Specification / Model | 100 | 200 | 600 | 1000 | 2000 | 3000 | |

|---|---|---|---|---|---|---|---|

| Main specification | Die Clamping force(kN) | 1,000 | 2,000 | 6,000 | 10,000 | 20,000 | 30,000 |

| Lifting capacity(kN) | - | - | - | - | - | - | |

| Stroke(mm) | 500 | 500 | 900 | 1000 | 1000 | 1,200 | |

| Daylight(mm) | 800 | 1,120 | 1,500 | 1,500 | 2,000 | 2,000 | |

| Descension speed(mm/sec) | 70 | 120 | 200 | 100 | 100 | 100 | |

| Die clamp speed(mm/sec) | 15.0 | 10 | 10 | 10 | 10 | 10 | |

| Ascension speed(mm/sec) | 100 | 70 | 100 | 100 | 100 | 100 | |

| Bolster size(mm×mm) | 630×630 | 900×900 | 1,600×1,600 | 2,000×1,800 | 2,500×2,500 | 3000×2,500 | |

| Bolster height(mm) | - | - | - | - | - | - | |

| Weight | - | - | - | - | - | - | |

| Power source | Die clamp pump | General purpose servo pump | |||||

| Rod cylider | |||||||

| Pierce cylinder | |||||||

| Hydro supply | Max Flow pressure(MPa) | 200 | 200 | 200 | 200 | 200 | 200 |

| Hydro Flow capacity(L/min) | 2.5 | 2.5 | 10 | 10 | 10 | 10 | |

| Max flow rate(L) | 0.5 | 0.5 | 2.0 | 2.0 | 4.0 | 4.0 | |

| Pressure generator pump | General purpose servo pump | ||||||

| Hydro saturation sensor | Automatic | ||||||

| Controller | PLC | ||||||

| Installation floor | Pitted floor | ||||||

| Loading device | Manual / Vacuum-hand robot, others | ||||||

| Unloading device | Manual / Conveyor robot, others | ||||||

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

Thanks to the DDV servo pump equipped as power source, energy-saving and unique hammering molding are realized to make low constant of friction between a work piece and mold for successful high propagation of a work piece.