Bending tools for pipe bender (for ECO/WIN Benders)

The best suited tools are designed based on the standard version for ECO/WIN Benders.

Product outline

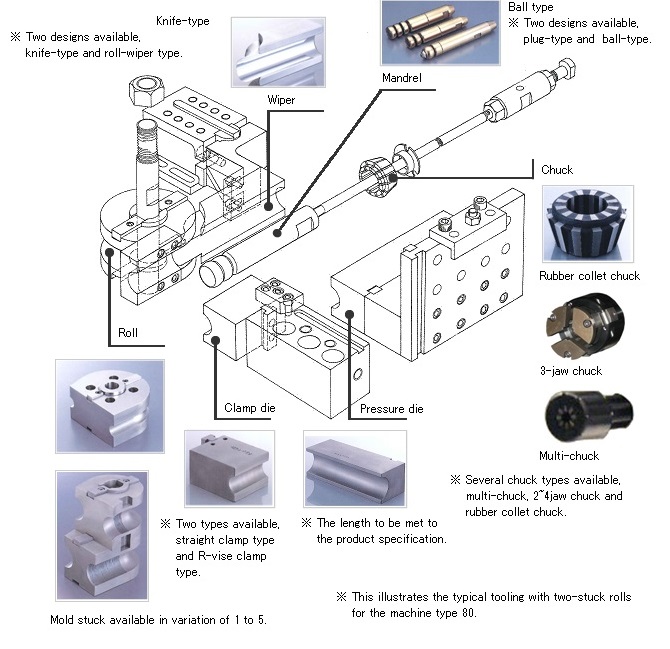

Illustrated components of standard tooling

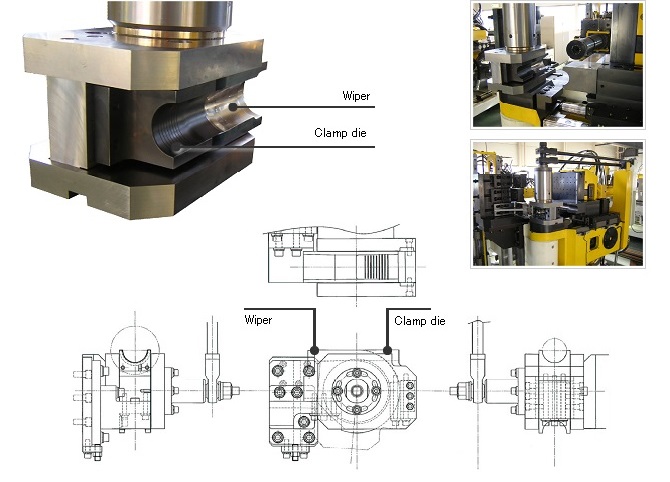

Roll wiper incorporated mold of Opton original

▼The total view

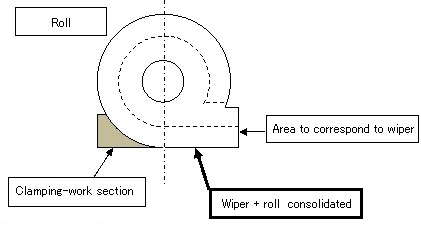

What is a wiper-incorporated roll ?

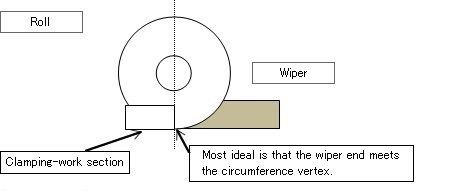

The image below shows the best-expected setting of bend roll and wiper being observed in standard set-up.

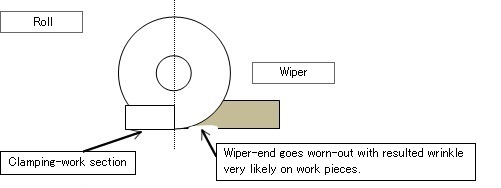

But in reality, mounting of a wiper is held as bending trial is performed that would often need time-consuming set-up and matured technical skill.

Another concern on this traditional mounting is that the material quality of wiper is most often that of alloy of cupper & aluminum. This is soft enough to keep inner surface of work pieces free from flow mark caused in the machining process, but thin-ended wiper is then very easy to wear-out with higher possibility likely of causing quality instability in mass-production run.

Roughly 2000 bend work is the time for maintenance of repair or replacement.

Consolidated structure of wiper + roll requires therefore, as shown in below, no calibration work neither of special technical skill for mounting which are indispensable in conventional installation.

Tic-coated die steel as the material can offer long-term, flow-free quality of work pieces.

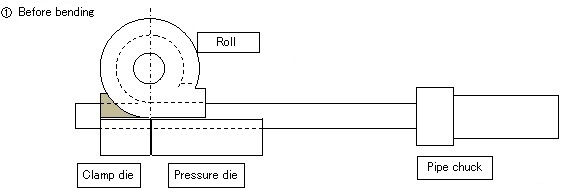

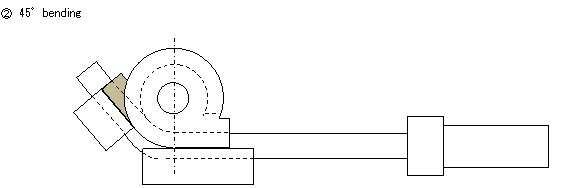

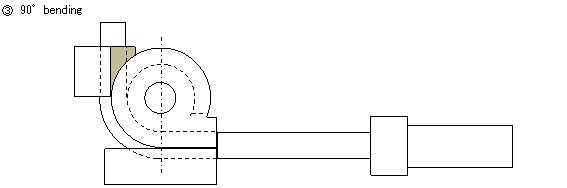

Illustrated motion of roll+wiper during machining

Features of wiper-incorporated roll

- Due to wiper being consolidated to the roll, no technical skill is needed for setting of the tool.

- Grooved section of the roll and wiper-corresponding section are Tic-coated. Comparing to conventional tooling, wear-resist service can be expected far longer than conventional wiper.

example φ50.8×R80 :3-bending 1000 pcs./day Served 36months at 20 days/month φ60.5×R120:3-bending 700 pcs./day Served 48months at 20 days/month φ65.0×R130:3-bending 700 pcs./day Served 48months at 20 days/month

- Consolidated structure of wiper + roll excludes causation of wrinkle during machining with more assurance for stable production quality.

Roll+wiper application by Opton clients

| Client A | ① φ76.3×t2.3×R130 ② φ42.0×t2.0×R 54 ③ φ38.1×t1.5×R 50 |

Suspension member pipe Intake manifold pipe Exhaust manifold pipe |

| Client B | ① φ80.0×t1.5×R120 ② φ54.0×t1.5×R 54 ③ φ48.6×t1.5×R 60 |

Muffler pipe Exhaust manifold pipe Exhaust manifold pipe |

| Client C | ① φ59.0×t2.5×R 65 ② φ25.4×t1.2×R 25.4 |

Intake manifold pipe Water pipe |

| Client D | ① φ25.4×t1.2×R 50 | Inlet pipe |

Many other applications available.

Features

- Standard tooling available in series

- The best suited tooling can be selected to meet product specification

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

The best suited tooling are offered that will work to achieve stable quality, reduced failure rate, shorter set-up time and other related problems. For any inquiry on the Opton tooling, please contact our sales representatives directly, or via HP inquiry window.