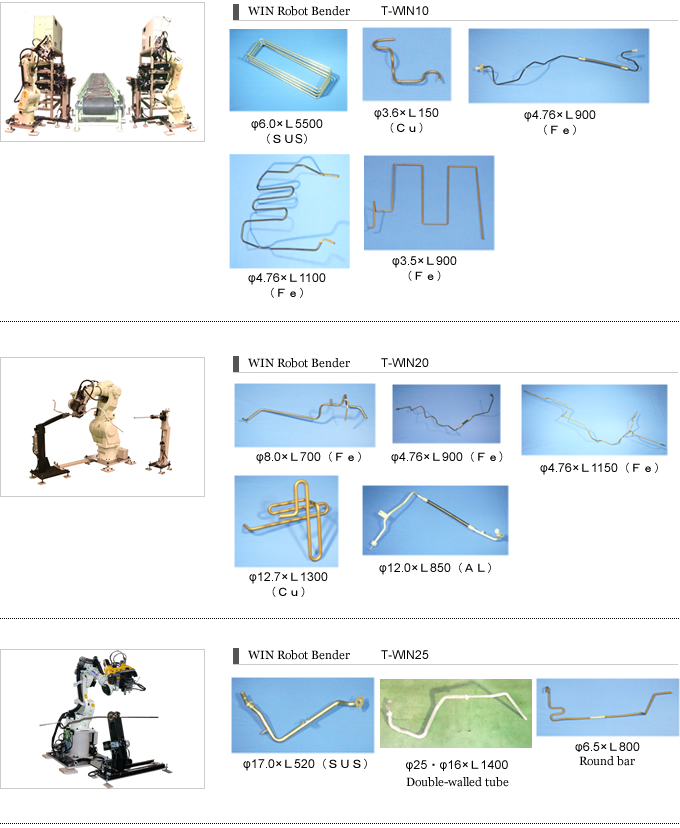

Robotic Bender Type T-WIN Series

World-patented robotic bender

The machine of high-end performance for work pieces with components mounted

Product outline

●Thanks to this feature, high speed motion is realized in all functions of straight pitching, 360-degree rotation and retraction.

●Operation of the machine is as easy as conventional bender by input of bending point data in the (XYZ) coordination

●Loading/unloading position data for the robot bender are handled in by the teaching box.

●A work piece can be chuck-held at any point of its intermediate section or at the end of work piece.

Two types of bending head are available, movable T-WIN or stationary G-WIN.

| Movable bending head (T-WIN) | Stationary bending head(G-WIN) |

|---|---|

| 5・8・10・15・20・25 | 35・45・50・60・70・80・85・90・100・130・150 |

Operational concepts, performance and tooling share much in common and interchangeable in corresponding capacity size between Oopton's conventional benders and robot benders.

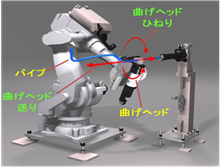

1.T-WIN : Movable bending head

The bending head unit is mounted on the robot arm end for all PRB motion with linear- and circular-interpolation implemented.

The bending head unit is mounted on the robot arm end for all PRB motion with linear- and circular-interpolation implemented.

Because of a work piece kept in fixed condition, high-speed and -accuracy machining is realized with its minimal swinging. This allows machining of complicated designs, quality stability as well as cost reduction which have long been refused in conventional machines and approaches.

Conventional production method has always needed to complete work piece with components of hoses and/or blocks in post and separated process. where in very often the cases are these components fixed only after a work piece being machined. This has only increased production process and accuracy instability.

Thanks to the enhanced capability of a bending head implemented on the robot arm end allowing its maximum interference-free motion, a straight work piece with pre-installed components can be machined, and thus shortage of process and increased of accuracy stability have come to reality

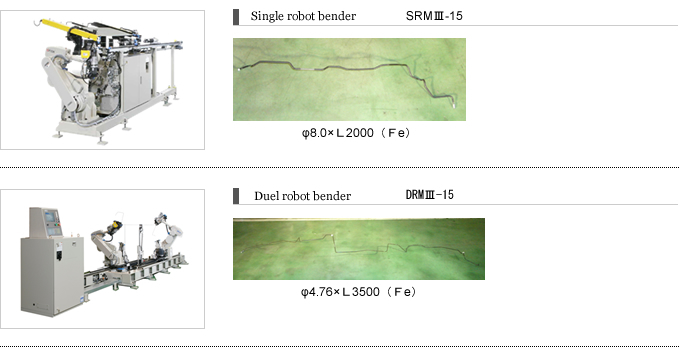

Another Robot bending

Features

- Method of data input and operation same as the conventional model

- Machining is accessible with a work piece with component at clearance position

- Four different designs can be machined and classified in the standard four (4) stocker loader

- Small R bending is in reality thanks to the power of NC mandrel

- Long work piece can be machined with the help of intermediate chucking

- With the help by one-point bender in attached location,continuous machining accessible including special designed bending.

- Case sample : Robotic bender in Opton’s cell system completes 24 seconds for 15 points bending of AL work piece against 1 minute of the same by conventional bender,

- Case sample : Successful Cell system of whole production line for air-conditioner pipe with rubber hose for its last bending process

- Max machining dia 16.0mm max. bending R 50mm

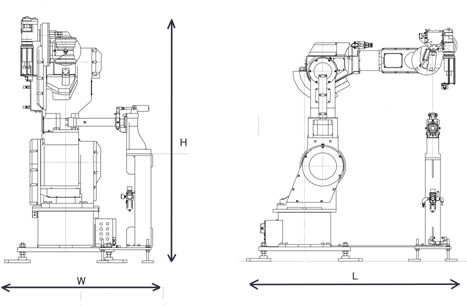

Out lined dimension

Series

| Type | T-WIN 5 | T-WIN 8 | T-WIN 10 | T-WIN 20 | T-WIN 25 | |

|---|---|---|---|---|---|---|

| Max size of work piece /thickness mm Max performance (for reference) |

SUS/mandrel | φ5.5×t0.5 | φ6.0×t0.8 | φ8×t0.8 | φ10×t1.0 | φ19×t1.5 |

| SUS/No mandrel | φ5.5×t1.0 | φ7×t0.8 | φ10×t1.0 | φ12×t1.0 | φ25.4×t1.5 | |

| STKM/mandrel | φ6.5×t0.7 | φ7×t0.8 | φ10×t1.0 | φ13×t0.7 | φ25.4×t1.6 | |

| STKM/No mandrel | φ6.35×t1.0 | φ8×t1.0 | φ12×t1.2 | φ16×t1.0 | φ31.8×t1.6 | |

| AL・CU/mandrel | φ7.0×t1.0 | φ8×t1.0 | φ12×t1.0 | φ18×t1.0 | φ32×t1.6 | |

| AL・CU/No mandrel | φ8×t1.0 | φ9×t0.8 | φ14×t1.0 | φ19×t1.0 | φ35×t2.0 | |

| Max stack of die | 4 | 4 | 4 | 4 | 4 | |

| Standard effective length of work piece variable by every 500mm |

800 | 800 | 800 | 1000 | 1000 | |

| Max bending R | mm | 40 | 50 | 50 | 50 | 70 |

| Per-bend time | sec | 1.0 | 1.2 | 1.2 | 1.5 | 2.5 |

| Std speed of NC axi | Feed mm/sec | 1300 | 2000 | 1800 | 1700 | 1000 |

| Twist °/sec | 650 | 360 | 320 | 290 | 180 | |

| Bending °/sec | 400 | 380 | 360 | 225 | 180 | |

| Std NC axis Repeatability |

Feed mm/sec | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| Twist °/sec | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | |

| Bending °/sec | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | |

| Machine weight | ton | 0.5 | 0.7 | 0.8 | 1.5 | 2.5 |

| Length(L) xWidth(W)xHight(H) | 0.8×1.2×1.4 | 0.8×1.2×1.5 | 1.0×1.4×1.5 | 1.3×1.7×1.6 | 1.6×2.0×1.5 | |

Bend-Master (BEM)

Bend-Master (BEM)

Supporting Software for Bending Bendmaster (BEM)

Bend simulation software

Bend simulation software

3D profiler for pipe

3D profiler for pipe

3D Profiler for Pipe

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

There are many production problems to solve, including cost-down, quality increase, production variety, one-piece production, elimination of running stock, instant full start-up, etc., and they are all in most cases hard to be cleared by conventional type of benders. Robotic benders from Opton are just the ones for solution at high end level.