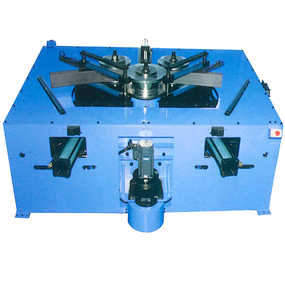

CNC Roll Bender (Bender with three NC rolls) AA

Three individual rollers are numerical-controlled simultaneously for their turn and positioning to achieve high-accuracy machining.

Product outline

●Opton is your proved and reliable supplier for roll benders.Three N/C rollers traverse individually to the best positions required to obtain the specified design of a part in time- and material-saving processes.

●Custom-ordered specialty plain bender, backed up by Opton’s featuring NC technologies, has been delivered to the market with implementing the advantages from two anteceding benders,or specialty roll bender for machining automobile bumper core frame as one, and conventional benders as the other.

●Conventional three-roller type benders whose rollers are traversed hydraulically or by hand may be suggested to consult with relevant suppliers.

●Custom-ordered specialty plain bender, backed up by Opton’s featuring NC technologies, has been delivered to the market with implementing the advantages from two anteceding benders,or specialty roll bender for machining automobile bumper core frame as one, and conventional benders as the other.

●Conventional three-roller type benders whose rollers are traversed hydraulically or by hand may be suggested to consult with relevant suppliers.

Application examplesAA

- Aircraft :Wing stringer Main structural frame of the wing where high accuracy machining needed

- Automobile: Bumper linkage Plain-surfaced components where varieties of R-finish must be implemented.

- Construction materials: Angular steel, channel bar, hardenability band steel Two-dimensional bending where variety of R-specifications need be implemented

- Exterior material: Angular steel, channel bar, hardenability band steel

- Others: Two-dimensional bending where variety of R-specifications need be implemented

Features

- Thanks to computerized data entry, free designed machining is allowed including non-symmetric or compounded R design.

- Each pair of rolls, or top and bottom, are numerically controlled for synchronized turn, thus to result in stronger pitching of work piece

- Thanks to numerical controlled pitching of work piece, high accuracy machining is given with slip-less grip and free from warp and twist of work piece.

- Bottom rollers are numerically controlled for positioning and orientation.

- Automatic orientation of bottom roller amid the process meets the optimized condition for the material to be machined.

- Small R bending of a large-dia material is machined thanks to compression bending at top-positioned roll.

Series

| Type | RB-30 | RB-40 | RB-50 | RB-75 | RB-90 | |

|---|---|---|---|---|---|---|

| Working capacity | Angular outernal bending | 30×30×t5.0 | 40×40×t5.0 | 50×50×t6.0 | 75×75×t9.0 | 90×90×t7.0 |

| Squared copper pipe | 30×30×t1.6 | 40×40×1.6 | 50×50×t1.0 | 60×60×t2.3 | 80×80×t2.0 | |

| Copper pipe | φ27.2×t3.0 | φ34×t3.2 | φ48.6×t3.0 | φ70×t6.0 | φ85×t6.0 | |

| Squared aluminum pipe | 30×30×t2.0 | 50×50×t2.0 | 70×70×t2.0 | 100×100×t2.0 | 120×120×t2.0 | |

| Flat bar | 40×t6.0 | 50×t6.0 | 65×t6.0 | 90×t6.0 | 110×t5.0 | |

| Roll dia | Top roll dia(mm) | 150 | 200 | 250 | 300 | 350 |

| Bottom roll dia(mm) | 100 | 150 | 200 | 250 | 300 | |

| No. of NC axes | 7 | 7 | 7 | 7 | 7 | |

| No. of bending | 2 or more bend per design | |||||

| Pitching speed max(mm/sec) | 170 | 160 | 150 | 130 | 100 | |

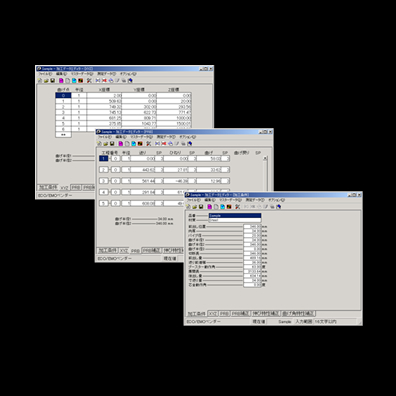

Bend-Master (BEM)

Bend-Master (BEM)

Supporting Software for Bending Bendmaster (BEM)

Bend simulation software

Bend simulation software

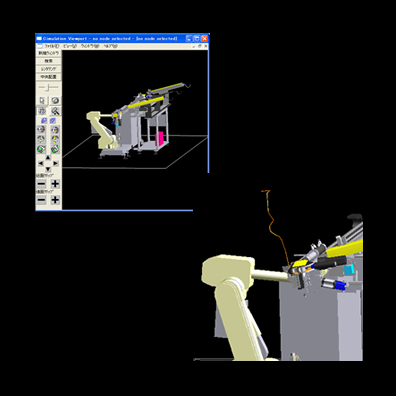

3D profiler for pipe

3D profiler for pipe

3D Profiler for Pipe

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

Opton proposes the best suited, tailor-made layout to meet the client’s specifications of work piece, or of cross-section design, material sizes and bending specifications needed.