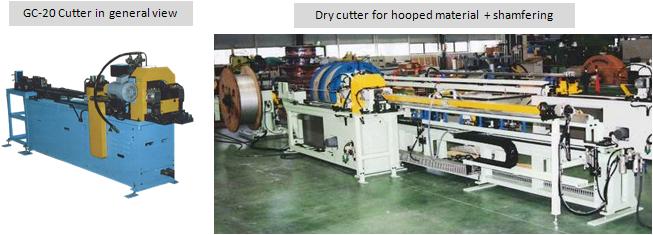

CNC Dry Pipe Cutter GC-20

This CNC pipe cutter is high quality, performance type of machine with no-lubricant type, an ideal version for smart and environment-oriented production line.

Product outline

The series is also available in two manners of material supply, one by the un-coiler type with straightening device for the material supplied in hoop, and the other by stocker type for the material supplied in fixed straight length.

Features

Following is the selection guide for the best model depending on the machining quality and cu-off mode to meet the client requirement.

⇒CNC Dry Cutter Series

2)For piercing and/or oblique cut-off

⇒CNC Laser cutter series

3)Cut-off and piercing of squared cross-section pipe

⇒CNC Laser cutter series

4)Pipe cutting in automated mode

⇒CNC Dry Cutter Series

⇒CNC Chip cutter series

⇒CNC Laser cutter series

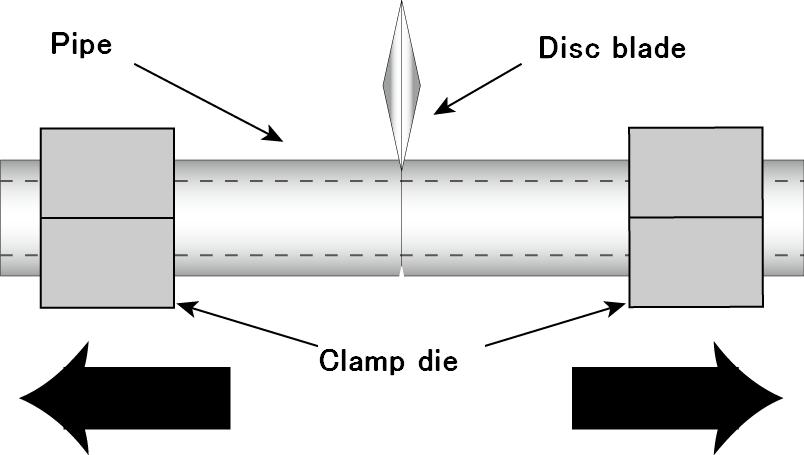

Tension &pull disc cut-off model

Tension &Pull Disc Cutting-off by CNC Dry Cutter Series allows no-lubricant, chip-and blur-free machining.

In Tension & Pull Cutting-off machining, unlike cut-off by mechanical saw-tip, a work piece is hold clamped for the tension applied towards opposite directions before a disc blade starts wedge cutting.

In Tension & Pull Cutting-off machining, unlike cut-off by mechanical saw-tip, a work piece is hold clamped for the tension applied towards opposite directions before a disc blade starts wedge cutting.

As the disc blade forwards for wedge-cutting of a work piece with tension applied to both ends, the thickness reduces too thin to withstand the tension, and the residual skin goes eventually ruptured. As the disc blade behavior does not end to push the last skin towards inner diameter, no blur is caused..

As the disc blade forwards for wedge-cutting of a work piece with tension applied to both ends, the thickness reduces too thin to withstand the tension, and the residual skin goes eventually ruptured. As the disc blade behavior does not end to push the last skin towards inner diameter, no blur is caused..

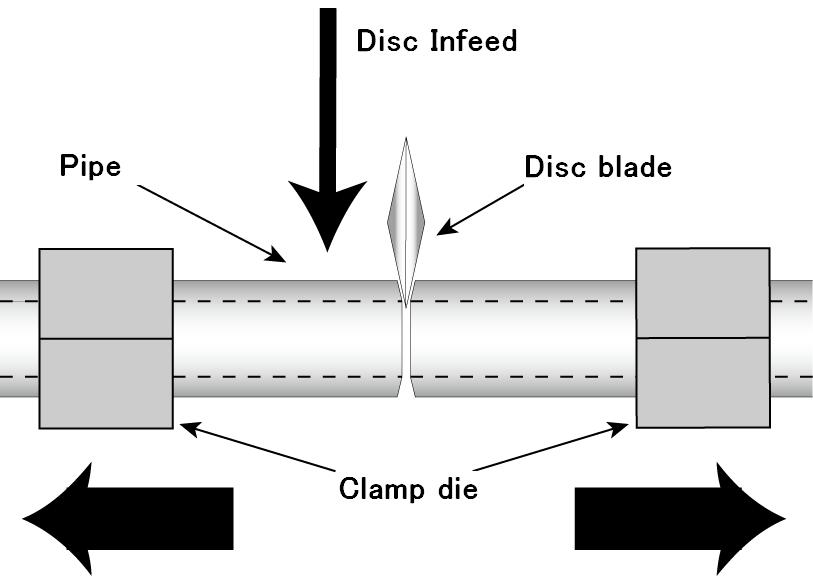

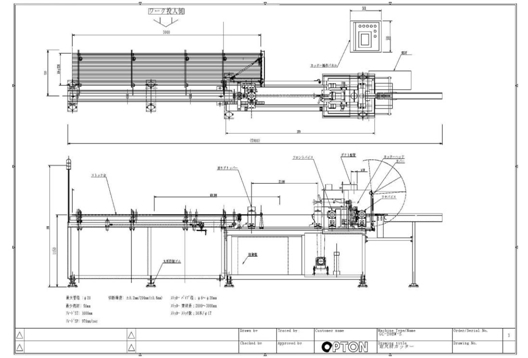

The Dimensional view of the Dry Cutter

①Type 20 Cutter Layout view with Uncoiler: The hooped pipe is pulled out of the uncoiler to be straightened by straightening rollers before the pipe is cut off.

By facilitating the optional discharger and stocker, cut-off pipes in different lengths are loaded to the assorting stocker.

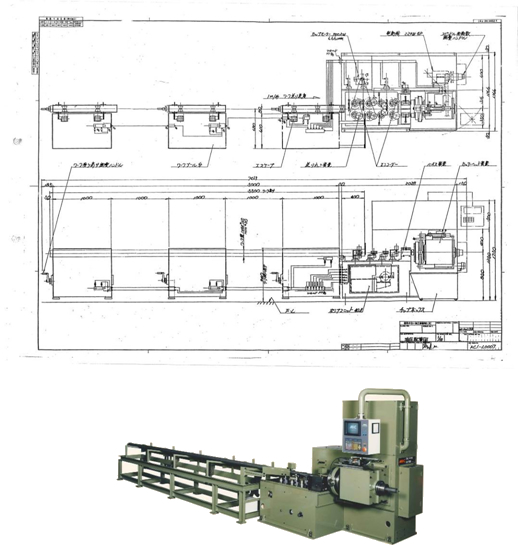

②Type20 Cutter Layout with the stocker for fixed size material A single piece of fixed-sized material is fed out of stocker to be forwarded to the cutter.

③Type 50 cutter Layout for material supply in a fixed size

ip cut-off Type

In CNC Chip-cutter series, the supplied material is cut-off by tip-saw. High speed cutting is also made to the material of large thickness. Chamfering device is available in option.

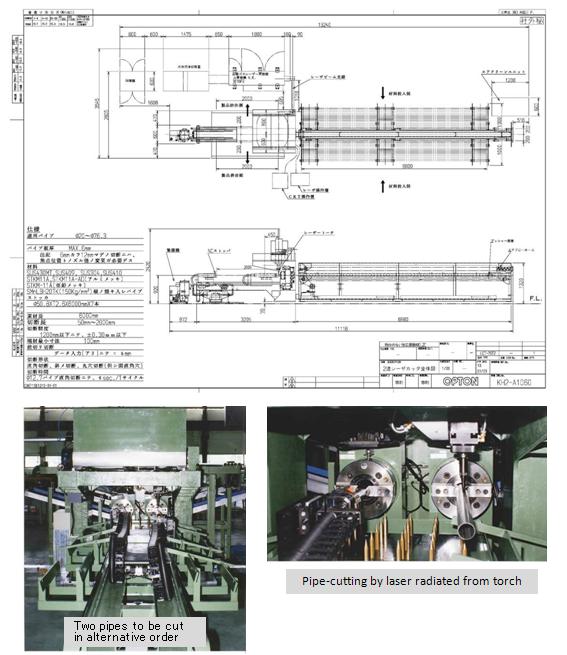

Laser cut-off model

Thanks to cutting-off by laser beam implemented in the CNC Laser Cutter series, no cut-off tool is needed thus making cut-off accessible to various sized material with no tool change needed for remarkable increase of operation rate.

Cut-off time by laser is shortened to 1/3 for increased productivity against other cut-off mode by mechanical cutting tools. In CNC Laser cuter, Material of fixed size is turned with CO2 laser beam alighted.

Piercing, oblique cutting are also available. The stocker are located in both sides of the machine to assort two different diameters of material.

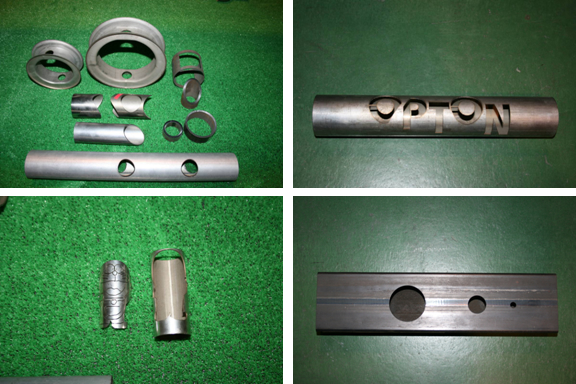

【Laser-cut off examples】

Features

- Shortening of the machining process

Wedge-cutting with tension applied towards two ends makes less blurs on both inner & outer diameters of material. - No cleaning needed

Thanks to wedge cutting by disc, no chip is caused to achieve environment-friendly machining floor. - Easy operation

Monitor-assisted dialogue-type data entry in the display. Helpful for easy diagnosis and maintenance

Series

| Specifications | Type20 | Type50 | Type80 | Type150 | Type200 |

|---|---|---|---|---|---|

| Material quality | Cupper・Al・SUS・Steel(STKM) | ||||

| Capacity (in OD, φmm) | 4~22 | 10~52 | 40~90 | 60~170 | 100~250 |

| Cut-length(mm) | 50~5500 | 70~5000 | 100~ | 200~ | 250~ |

| Cycle time | 3~5sec | 5~9sec | 7~10sec | 9sec~15sec | 12sec~20sec |

| Reference*1 | |||||

| Machining accuracy | ±0.2mm以下 | ±0.3mm以下 | |||

| (For cut length of 500mm) | (For cut length of 500mm) | ||||

| Material supplied in | Fixed/Hooped | Fized | Fized | Fized | Fized |

| Pitching distance | 1,000 | 1,000 | 2,000 | 2,000 | 2,000 |

| (per stroke) | |||||

| Applied mode of tension | One/Two sided | One/Two sided | One/Two sided | One/Two sided | One/Two sided |

| Cut-off mode | Disc blade | Disc blade | Disc blade | Disc blade | Disc blade |

| Tip | Tip | Tip | Tip | Tip | |

| Blade travel | Pneumatic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Hydraulic | NC | NC | NC | NC | |

| NC | |||||

| Control | PLC | PLC | PLC | PLC | PLC |

| NC | NC | NC | NC | NC | |

*1 500mmThe figure indicates the value right after the machining, and may be varied depending on the material quality, finished accuracy required etc.

Special and custom specification is met upon request.

| Specification | Type75 |

|---|---|

| Type of pipe | Round / squared cross section |

| Pipe quality | Cupper・Al・SUS・Steel(STKM) |

| Thickness | MAX 6mm |

| Capacity(OD φmm) | 20φ~76.3φ |

| Cut length(mm) | 50~2000mm |

| Machining time | 6sec |

| Ref.*1 | |

| Accuracy | Less than ±0.3mm(for cut-length of 500mm) |

| Stocker | Fixed size of 50.8φ, 6000mm×7pcs x 2stockers |

| Machining mode | Alternative cutting of two sizes |

| Cut-off design available | Straight, oblique, piercing, irregular-designed piercing |

| Type of laser | CO2 Laser |

| Controller | NC |

*1 for φ20 pipe at straight cutting

Machining time may varies depending on the material quality, thickness etc.

Special and custom specification is met upon request.

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

Opton has, with years-long involvements in pipe-working business, successfully made various pipe cutter machine available in series for varied requirements. Custom specification can also be met upon consultation.