3D Pipe Bending Interference Simulation System

Off-site work for interference-free bending data

Product outline

●Imaging and storage of the best suited die

●Imaging and storage of production cell

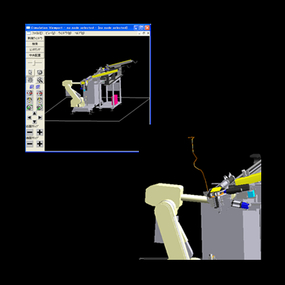

●Imaging of 3D simulation

1.Imaging and storage of the best-suited machine

Data base input system corresponds to DXF/HPGL for 2D data and STL/IGES for 3D

2. 3D tool modeling and data preservation

Data base input system corresponds to DXF/HPGL for 2D data and STL/IGES for 3D.

3. Creation and preservation of production cell data

Production cell data for (virtual pipe bender) are created for the machine type and matching tools as specified in 「1. 3D machine data creation and preservation」 and 「2. 3D tool modeling and data preservation」as above Creation and preservation of the production cell data is executed for the 3D machine data and tooling 3D data in one set.

4. Display of 3D simulation

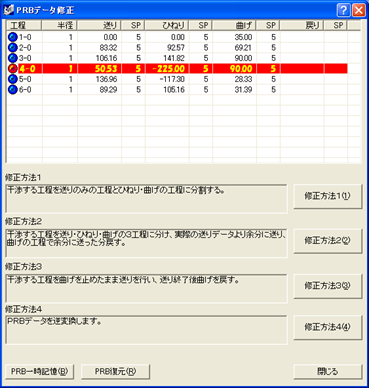

●When interference is found, dialogue-type data correction is selected for creation to modify for interference-free machining program.

●Machining cycle time can be checked during the simulation.

Feature 1:Virtual 3D motion

Virtual 3D machine motion shows all processes of loading, machining and unloading.Friendly animated display provides easy visual check of robot movement and work design achieved in intermediate processes.

Virtual 3D machine motion shows all processes of loading, machining and unloading.Friendly animated display provides easy visual check of robot movement and work design achieved in intermediate processes.

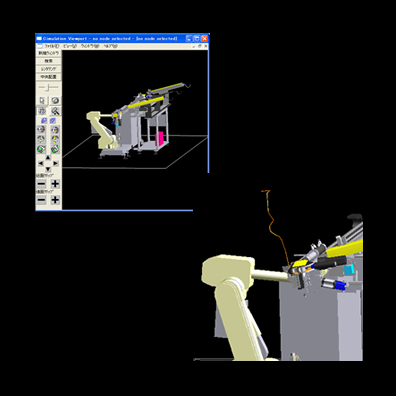

Free-selection view angle further offers very unusual but convenient visual check for machine movement viewed from the floor and/or the close-up view of the bending head.

Feature 2:Automatic interference check

Interference check is made at an intermediate process for positioning of a work piece vs machine.When interference is found, detailed status can be checked for position and process .with the animation mode being stopped.

Interference check is made at an intermediate process for positioning of a work piece vs machine.When interference is found, detailed status can be checked for position and process .with the animation mode being stopped.

Feature 3:Self correction for interference-free machinnig

When interference is found existing in the process, this simulation soft executes automatic diagnostic to free from interference and also provides the solution to an operator. The operator simply follows the selective guidance appeared in the screen to renew for interference-free program.

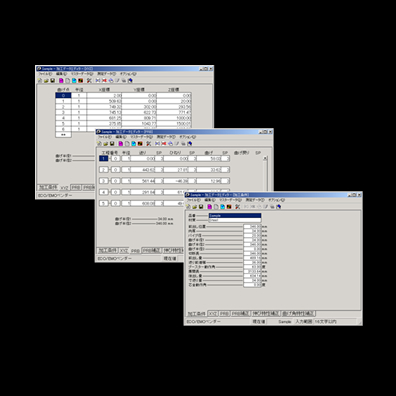

Feature 4:Free data editing

Computer-processed data are helpful for extended data edit for various test machining.

Easy data transfer with HD or FD is convenient for preservation and call of the data.

Feature 5:Easy handling of the data to/from the machine

This simulation software corresponds to the file format of the robot bender, data out from the machine and editing by a FD is easy.

Feature 6:Graphical user interface

The system is operated on Windows2000/XP and data editing and/or animated operation can be made with using mouse and key board. As the data edit screen also corresponds to those of Opton benders, operation will be very easy for those who know Opton machines.

Feature 7:Customization of the tooling

This simulation system contains the standard-designed bending toll for immediate and convenient application upon the software installed in the PC. Customizing application is also included in the software for free custom designed mold simply by input of dimensional data for original mold. This original mold data can be stored in the data base for animated application.

Feature 8:Simulated check of the material behavior

As the characteristic on elongation and spring-back can be reflected in the data, interference check is easy with these material characteristics considered in the program.

Feature 9:Help Function

Descriptive reference is made for screen and parameters as convenient help call at any time needed.

Series

| Article | 内容 |

|---|---|

| CPU | Pentium 3 or up |

| Memory | 512MB以上 |

| OS | Window XP |

| Operation | Mouse & key board |

Bend-Master (BEM)

Bend-Master (BEM)

Supporting Software for Bending Bendmaster (BEM)

Bend simulation software

Bend simulation software

3D profiler for pipe

3D profiler for pipe

3D Profiler for Pipe

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.