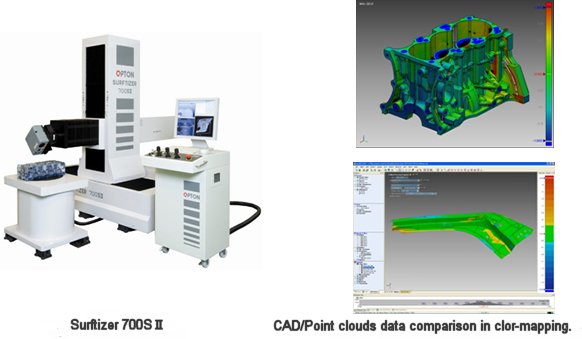

Surftizer Series

Speed- , accuracy- and density-oriented 3D profiling

Product outline

Various sizes available in the series to meet the sizes of a testing specimen ( 300SII, 700SⅡ、2000LⅡ、6000LⅡ) with 3D camera installed to all models. Co-axial laser probe and touch probe are also available as option.

In addition to the existing automatic profiling at the teaching playback mode, a new optional feature can now be embedded where the outlined design of a specimen can also be profiled in fully-automatic operation in y travelling a camera alongside of the surface of the specimen.

Features

- The Surtizer Series executes an optional performance of fully-automated profiling by processing the compound data obtained from tested 「patch-size」 and 「point」 data. This will free an operator from test-related works.(Optional)

- Convenient automatic profiling by the teaching-playback mode is also available for testing of n-quantity of work pieces and/or testing of pre- and post-modified molds.

- Available as optional feature is the testing using co-axial sensor and contact-type touch probe for the areas on the vertical wall in narrow space, the side and bottom of the hole.(optional)

- 4. The tested point-cloud data can be expressed in color-mapped comparison of the data with 3D CAD data. The tested data can be also output in various reporting forms as needed. (Optional software needed.)

- 5. Thanks to high definition point-cloud data, precise data merging can be achieved for reversed engineering. (Optional software needed.)

Out lined dimension

Series

| Model | Surftiser 300SⅡ |

Surftiser 700SⅡ |

Surftiser 2000LⅡ |

Surftiser 6000LⅡ |

||

|---|---|---|---|---|---|---|

| Camera type | GigE x 1 | GigE x 1 | GigE x 1 | GigE x 1 | ||

| Co-axial laser sensor | Optional | Optional | Optional | Optional | ||

| Touch probe | Optional | Optional | Optional | Optional | ||

| Rotary table | φ300 | φ525 | Optional | Optional | ||

| Profiling view size(mm×mm/patch) | 70×55 | 70×55 | 150×120 | 150×120 | 150×120 | |

| Focal distance(mm/mm at center depth) | 170 | 170 | 300 | 300 | 300 | |

| Working depth(Focal distance±mm) | ±20 | ±20 | ±50 | ±50 | ±50 | |

| Quantity. of point clouds | 1.4/5milions | 1.4/5milions | 1.4/5milions | 1.4/5milions | 1.4/5milions | |

| Minimum pitch between tested points in the clouds | 1.4mil pixcels(mm/XY) | 0.06 | 0.06 | 0.12 | 0.12 | 0.12 |

| 5mil pixcels(mm/XY) | 0.04 | 0.04 | 0.08 | 0.08 | 0.08 | |

| Testing time in 4/12 shift | 1.4mil pixcels(sec) | 5/10 | 5/10 | 5/10 | 5/10 | 5/10 |

| 5mil pixcels(sec) | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | |

| Guaranteed accuracy | flat surface / step gauge in absolute value | 10/15 | 10/15 | 15/20 | 15/20 | 15/20 |

| plane/step/sphere in repetition | 4/5/10 | 4/5/10 | 8/10/20 | 8/10/25 | 8/10/30 | |

| Field of view | φ300×300 | φ700×500 | φ700×500 | 2000×550×800 | 5400×1400×2400 | |

| Automatic and high-accuracy patch merging by moving NC axis | ◎Automatic | ◎Automatic | ◎Automatic | ◎Automatic | ◎Automatic | |

| Product size W×H×D(mm) | 900×1300×900 | 1950×2050×2050 | 4250×2450×2650 | 8400×4500×2750 | ||

| Gross weight (kg) | 640 | 1650 | 3850 | 8000 | ||

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

This axial travelling 3D Non-contact profiler with 3D digital camera installed execute controlling of camera’s relative positioning to a tested specimen which is checked in fully automatic control operation (optional).

The camera traverses on the surface of work piece for 3D profiling in speed-, accuracy- and density-oriented operation.