Patended DDV Hydraulic Servo Pump Series

The power of super-excellence backed by high-precision and energy-saving hydraulic control

Product outline

●No magnetic valve is used to control cylinder operation of forwarding, receding, thrust force, speed yet at higher accuracy than those of servo valve.

●Unlike the servo valve that operates for ON/OFF of hydraulic circuits, this system requires no hydraulic coolant, thus leading to save-energy operation.

●Unlike the conventional hydraulic system, no large-sized hydraulic tank needed, with eventual result of no large noise generated.

1.Two major application available of DDV hydraulic Servo Pump

- This product, once installed as a hydraulic source to a new production facility, energy- &,space-saving yet with higher accuracy performance becomes realistic to make advantageous difference with competitors.

- This product, if installed in a package for replacement to an old production facilities, all disadvantages currently existing will find out the way out.

2.Opton's DDV Hydraulic Servo Pump by features.

-

High accuracy and longer stability

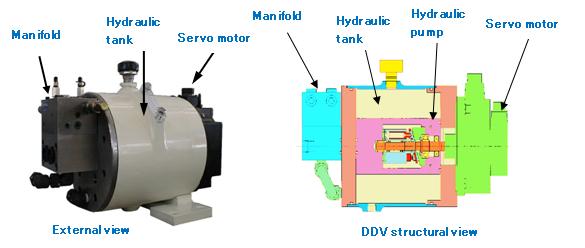

DDV Hydraulic Servo Pump is composed of two main mechanics connected in hybrid design concept,one is a reversible piston pump powered by non-leak type constant volume hydraulic media and the other is AC servo drive.Operation concept is that three operation factors of the cylinder, or velocity, direction and thrust force are controlled by the number of turns, direction and torque of AC servo drive.

This means that the piston pump works as hydraulic-powered reduction gear installed at the AC servo drive,and therefore requires no magnetic valve that is a must for conventional hydraulic system.This leads to an advantage of high operation accuracy totally uninfluenced by oil temperature, thus can utilize almost full performance of AC servo drive.

- Thermal and noise generation in negligible level

Conventional hydraulic servo valve causes high heat generation by actuator oil passing in a narrow throttle valve,and more than 50% of the total electricity is wasted as heat with the balance only left for effective power.A large hydraulic container and complicated distribution system and pump resonate to create uncomfortable noise.

DDV hydraulic pump, thanks to no throttle valve needed and the pump staying stopped when the cylinder at its halt-mode,causes heat generation at only 5% or less worth of total input electricity or more than 95% for real works.The noise would be leveled at only 1/10 of the conventional system.

- DDV with small-sized air-cooled tank against conventional system with large-sized tank

Conventional hydraulic system normally needs large-sized hydraulic- and water-tank to avoid heat-derived deterioration of hydraulic quality.The DDV Pump, thanks to non-leak type system, causes little quality deterioration only from minimal level of heating,thus no large-sized tank needed and hydraulic media required only 1/10 or less as that of conventional one, and air-cooling system is sufficient.

- DDV pump applications

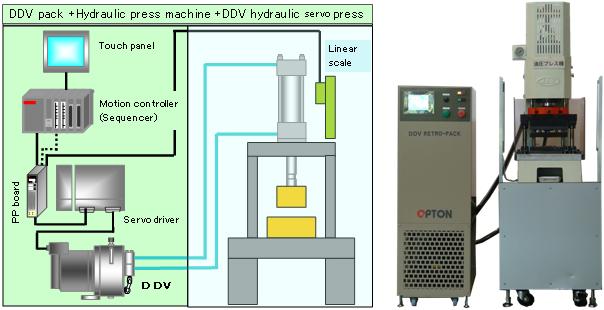

Save-energy & accuracy enhancement of an existing machine with servo-valve type hydraulic system A complicated hydraulic distribution system with magnetic valves and a large-sized tank are removed and a linear scale is mounted on the NC axial cylinder.

One DDV pump is mounted to the machine having the cylinders being controlled for sequential operation,while as much DDV pumps as that of cylinders needs be installed to the machine with the cylinders for parallel operation.By this new DDV-control system being implemented, an existing production equipment is dressed to the one of the latest version

- Application to a new machine with size-, energy-, and accuracy-oriented design

Conventional AC servo drive +ball screw can be replaced by DDV pump + hydraulic cylinder. By this implementation,the instantaneous operation torque rises three times as high for several seconds, which would be ideal for instantaneous-power required press-work.Further advantage is mechanical machine failure will be substantially reduced thanks to the shock-absorbing performance by the hydraulic cylinder.

- NC Pipe bender with servo-valve that is replaced by DDV system

For accuracy-oriented work, low heat generating DDV pump is ideal to replace accuracy-needed boosters for power supply and pressure-die that needs be eased from heavily influence by large hydraulic temperature variation through morning and day time.

- Cost

Conventional idea has been like employment of many single purposed magnetic valves, complicated distribution system to control cylinders.Now with DDV pump available in the market, AC servo drive will only control a reversible hydraulic pump for the total cylinder control.

No large-sized tank, magnetic valves nor distribution system needed, which is a big cost cutting.More than standard cost cut should be stressed for the machine with several cylinders on sequential control,while the machine with the cylinder on parallel control. remaining standard in terms of the cost.

3.Packaging of DDV pack/DDV pump and controller unit

This is a cost oriented version of DDV Hydraulic Servo Pump and NC unit combined.

With this DDV pack being once employed,general purposed hydraulic machinery currently in service are easily upgraded to that of NC version and/or new designed NC machinery are also of easy access with supporting team from Opton.

4.Typical machine model with successful installation of DDV hydraulic servo system

The machine of Opton brand

CNC Pipe Benders, CNC Hammering Hydroformer, CNC Multi Bender, CNC Multi Bender, CNCc Stretching Benders

Installation of DDV Hydraulic Servo pump to the production equipment by client's make

Opton has ever delivered this package as many as about 1000 units to be installed to various types of machinery that clients have made out of their own design.

The machinery include press machine, powder press-molding machine, insertion machine, press-brake, injection molding machine, tire-inflator,tire-wheel caulking machine, spinning machine, blow-forming machine, sheet-spring press machine, sheet-spring conveyor line. Press-die cushion,casting-gate controller, rolling machine, roll former, rolling machine for paper production, end-former, press-cutter, film winder, bulge former, tube expander etc.

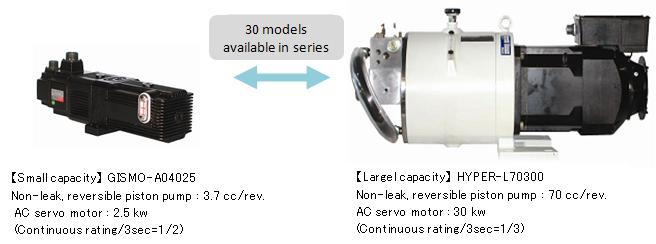

Series

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.