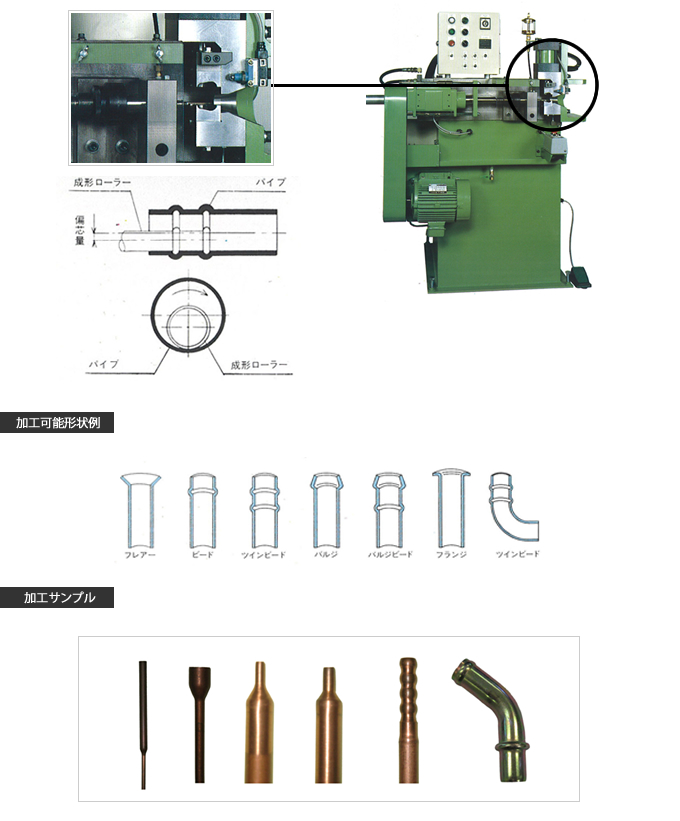

TC-10 Endformer with eccentrically-centered-die

High-precision and -speed end-former that can meet machining of work pieces with small thickness and for section close to R-section.

Product outline

High-precision and –speed end-former that can meet machining of work pieces with small thickness and for section close to R-section.

Features

- Small thickness and section close to R-section can also be machined.

- Beading and vulging are formed by turning the eccentrically-centered roller in traverse inside a work piece with no force being applied in axial direction

- The operator box is located in an easy-to-access location thus securing an operator free from operation error.

Series

| Unit | TC-10 | TC-40 | |

|---|---|---|---|

| OD×Thickness | mm | φ20×t0.8(Cu) | φ55×t1.0(Fe) |

| Die Forwarding Speed | mm/sec | 0~50 | 0~50 |

| Advanced positioning accuracy of die | ±mm | 0.05 | 0.05 |

| Max press | Mpa | 3 | 3 |

| Machine size | mm | L1100×W760×H1190 | L1200×W1400×H1100 |

| Machine weight | Kg | 650 | 970 |

| Electricity requirement | Kw | 1.9 | 3.7 |

Inquiry and/or consulation

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

Contacts are most welcome to Opton/MiiC sales group at following telephone number.

America:+1-734-453-2188

Mexico:+52-55-5203-3027

German:+49-89-540165-12

Japan:+81-561-48-3382

Sales affiliates of Opton group

We have sales locations in USA, exico,Germany and HQ in Japan.

We have sales locations in USA, exico,Germany and HQ in Japan.

There are many production issues to solve in tube bending business including cost-down, quality grade up, small volume production with variety designs, reduction of in-production inventory etc, Opton's End-formers can be claimed as solution machines to these problems. If needed, optional features can be met depending on the problems.